AIO Coldplate surface nickel plating practical application …

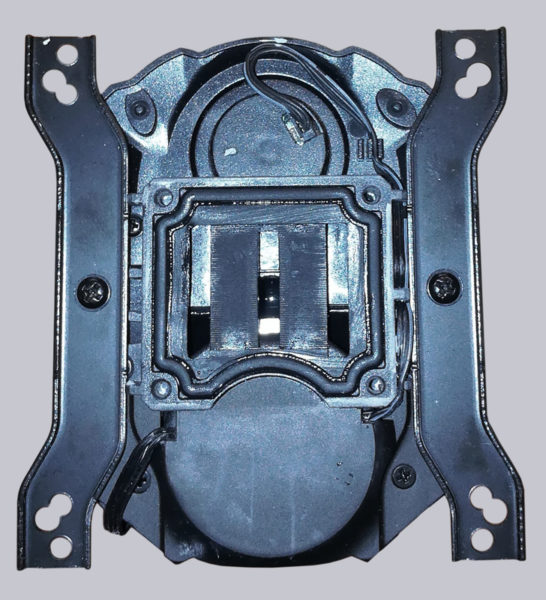

After our first attempt worked out well, we’ll now try nickel plating a copper CPU cooler. To do this, we first unscrew the coldplate of our Arctic Liquid Freezer II 360 water cooler. If you hold the cooling block vertically upwards during disassembly and fix it that way for the time of nickel coating, then you can close the cooler again later without having lost a drop of water from the cooling circuit. You only need to lean the cooling block against a wall, as the hoses are strong enough to hold the cooling block securely up. If you cover the open cooling block with some foil, dust will not get into the water circuit.

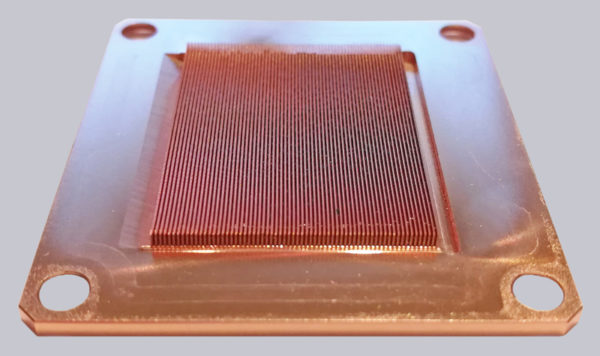

On the back of the copper part are the fine cooling fins around which the water flows. These fine channels we do not want to nickel.

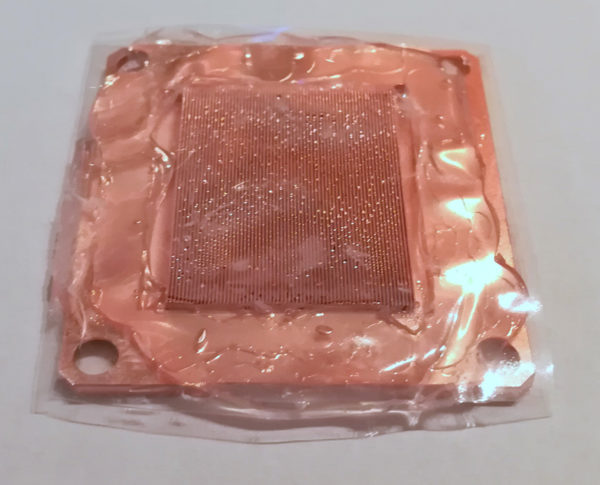

Therefore, we tape off the back of the heat sink with foil and hot glue so that the electrolyte does not reach this area of the component. A test with tap water shows that our makeshift is really tight. Alternatively, you could also fix the AIO coldplate in the electrolyte in such a way that only the bottom side is immersed in the electrolyte. Furthermore, contact devices for hand electroplating or laboratory electroplating with a small electroplating tank are also commercially available, where the object is placed on a contact plate and then a previously immersed electroplating pocket is pulled over the object to be electroplated, or even by means of a hand electroplating pen and nickel rod electrode, an object can be specifically chromium-plated or nickel-plated. Such a contact device is already available for a few euros at Amazon *Ad.

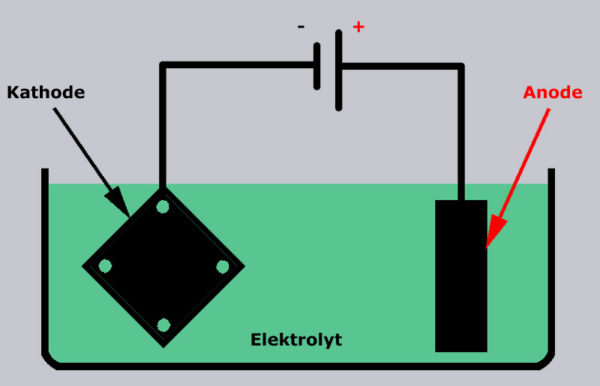

So get on with the electrode and put it into the electrolyte.

Then switch on the power supply and wait.

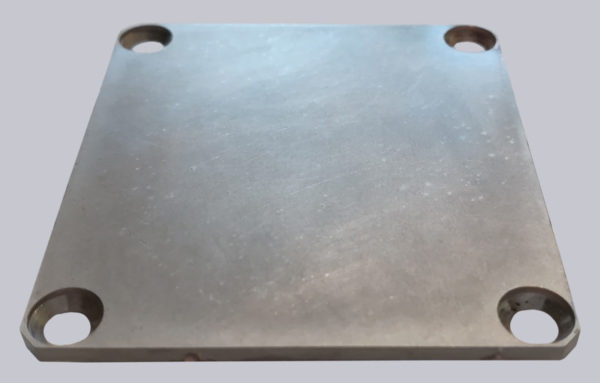

After a few minutes, we remove the cooling plate from the nickel bath and examine the result. It is not quite as beautiful as the coin, but the surface is completely covered with nickel. In reality it looks a bit better, even if the result on the photo looks a bit blotchy. Certainly, the appearance of the nickel layer could be further improved with additives such as boric acid and saccharin, and by accurately measuring and adjusting the PH of the electrolyte. Commercial companies also pickle the parts to be plated before finishing, but we didn’t do that either, since handling such chemicals isn’t exactly beneficial to both people and the environment.

Installation in the PC

For the following performance test, we use our well-known AMD system with Ryzen 2600 CPU.

| CPU | AMD Ryzen 5 2600 @ 4GHz / 133W |

| AMD Mainboard | ASUS TUF B450M-Pro Gaming |

| RAM | 2x 8GB DDR4-3200 CL14 |

| Umgebungstemperatur | ca. 21 °C |

Improve nickel plated AIO with liquid metal …

We reinstall the now nickel-plated cooling plate into the water cooling system and next we prepare the PC for the use of liquid metal (see Liquid Metal Guide). Since liquid metal is electrically conductive, we need to protect the computer from dripping liquid metal causing a short circuit. To do this, we install a drip cup below the CPU socket, which is placed on 2 spacers. The spacers with 1mm height are necessary to prevent the drip cup from resting on the SMD components on the mainboard. In the following photo the upper CPU cooler holder is already mounted and the washers for the drip tray are placed on the lower two spacers for the CPU cooler.

We designed the drip cup ourselves and made it with the 3D printer. If you have any questions about 3D printing, please feel free to visit our 3D Printer Guide or our 3D Printer Forum and share your experiences or ask for advice – we are happy to help. The easy-to-print component is approx. 0.1mm thinner than the CPU cooler’s spacer bolts protruding over the washers. This ensures that the CPU cooler is still mounted at the correct height.

This is what the drip tray looks like when installed. The CPU has also already been freed from the old thermal paste.

Before the CPU cooler is mounted, the last step is to apply the liquid metal. This is best done in a horizontal position, as the liquid metal has a watery consistency and flows down immediately. As always, with liquid metal, less is more. So we apply as little as possible and the surface is just wetted throughout.

Finally, the CPU cooler is mounted and the PC is ready for use again.

AIO water cooler nickel plating results …