Layout, Design and Features …

Let’s first take a look again at the whole shift knob.

Now let’s look at what makes him so special. On the one hand there are the connection cables that allow a direct connection to the Thrustmaster T300RS.

On the other hand we have a USB connection cable, which can be used in combination with any other wheel.

Unfortunately, the 9-pin connector is a special production which are not to buy commercially. Protected by a screw connection and strain relief, however, this cable should provide many years of reliable operation.

The set also includes a shift knob, which has a diameter of approximately 6 cm.

This can, as already mentioned in the specifications, be replaced by any suitable commercial knob.

Here, however, you should be careful to protect the thread of the shift rod, since most knobs are fixed by a screw, which could damage the thread. Plastic caps are supplied, but offer little protection. However, there is also the possibility of using the small bore in the shift rail for fastening, if provided from the knob.

Tip: If you screw a metal shell – available in any well-stocked DIY store – at the bar, so you can fix the shift knob safely.

Also located in the carton, a plastic plate, which can replace the metal plate by means of the four mounting holes.

Characterized the control rod is fixed in the center position, and allows a very short sequential shifting way.

This is made possible by a spring mechanism on the bottom, which returns the shift rod after shifting to the center position.

Now we come to the actual base unit. When unpacking, you were able to see how massive the gear shift is processed. This impression also continues with the bracket.

Both the plunger and the base plate are fitted with a rubber sheet in order to protect the table surface as much as possible.

Unfortunately, they have failed to protect the table edge also with such a protective equip. But the resourceful OCinside users there knows how to certainly help to protect his table edge. After mounting, the unit is fixed bombproof at the table and can not even be moved by heated switching maneuvers.

At the bottom there is a large hole where the connecting cable is led out. The interesting thing is that this is large enough to push the connector end through also. This is to remove the entire “inner section” after removing the circuit board and a further cover.

Laterally there is an opening that has caught our attention. Behind can be seen, in the standard position of the shift gate, a large screw, by which you can adjust the resistance of the shift rod. From pony-soft to rock-hard you can tweak to the individual needs.

The quality of the metal parts is really good.

The massive metal plate with H-circuit guides the shift rod reliably in the respective grade.

After loosen the four Allen screws, it is possible to twist the circuit according to your needs, in order to utilize either type of installation.

Nevertheless, at this point, the warning should not be missed, never insert your fingers in the shift linkage.

Thrustmaster TH8A USB Software …

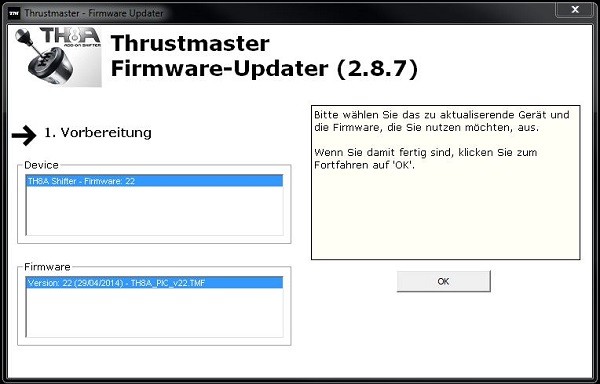

The software should be mentioned here. As would be the one of the Firmware Updater …

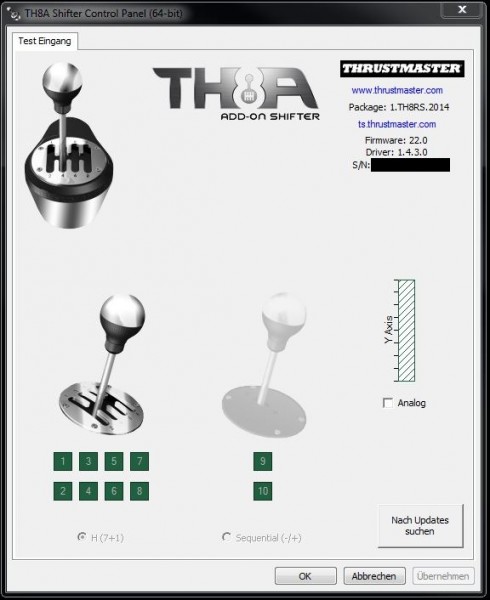

… and the overview of which function is currently active.

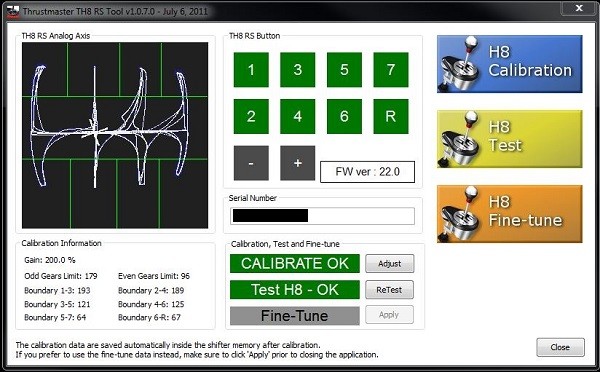

In addition, you can still download a Calibration Tool from the Thrustmaster website, which makes it possible to calibrate the shifter and to do some fine-tuning.

All in all you can say that Thrustmaster has put in the design and manufacturing a lot of effort to offer the gamers the ultimate in realism for the purchase price. Whether this is noticeable even when playing, we clarify for you based on the current racing and transport simulations.

Thrustmaster TH8A Installation and operation …